DEKRA TIC Testing, Inspection, Certification Ltd.

+36 1 417 3157 (36) 1 417 3163 VEIKI-info@dekra.com Visit website

Vasgolyó u. 2-4

Budapest, H-1158

Hungary

Overview

Key Contact Personnel:

Zsolt Kurucsó, Managing Director zsolt.kurucso@dekra.com

Balázs Varga, Head of Laboratories balazs.varga@dekra.com

Gábor Huszl, Head of High Power Department gabor.huszl@dekra.com

Csaba Homok, Head of High Voltage Department csaba.homok@dekra.com

Norbert Menyhért, Head of HC Department norbert.menyhert@dekra.com

Zoltán Ferenczi, Head of Certification Office zoltan.ferenczi@dekra.com

Year Founded

HV Lab: 1962

HP Lab: 1958

Total Number of Employees:

50

Services

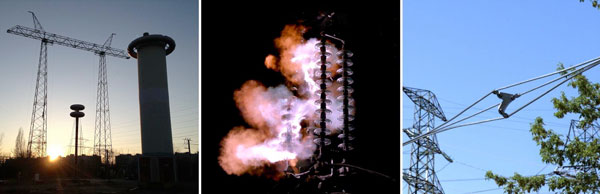

High Voltage Laboratory

Dimension of Main Test Hall: 40 m length x 20 m width x 18 m height

Dimension of Secondary Test Hall: 8 m length x 10 m width x 10 m height

Dielectric Testing Facilities

| Impulse Testing: | Max. Volt. | Standard |

| Lightning Impulse | 3400 kV | IEC, ANSI |

| Switching Impulse: | 2800 kV | IEC, ANSI |

| Steep front wave | 3000 kV/µs | IEC |

| Faraday cage (5mx5mx4m) | 60 kV, 1 pC | IEC, NEMA |

| Other Tests | ||

| A.C. Testing: | 1400 kV | IEC, ANSI |

| D.C. Testing: | 200 kV | IEC, HD |

| PD & RIV Testing: | 700 kV | IEC, NEMA |

| Heat Cycle Tests: | 75 kV, 2000 A | IEC, HD |

| Capacitance &Tan ∂ Testing: | 700 kV | IEC |

| Salt fog & humidity tests: | 30 kV | IEC, HD |

Salt Fog Test Facilities:Two fixed test chambers with dimensions (L × W × H):

4m × 2m × 2.2m

4m x 2m x 3.5m

Ageing and Material Tests:• Test chamber for 5000 h ageing test on composite insulators according to Sub-Clause 7.2 of IEC 62730-2012 Standard; flammability test on composite insulator housing materials.

• Test chamber for UV test on silicon rubbers of the composite insulators (Method A Cycle 1 according to Table 4 of ISO 4892-3).

Other Tests Performed on Insulators, Arresters, Bushings, Cable Terminations:Corona tests with day-light UV camera for detection of visible corona, and flammability test on cables. Tests with infrared thermo vision camera.

High Power Laboratory

Kind of Power Source for the HP Laboratory:Network supplied

Specifications of Main Test Bay

Possible Power Frequency:50 Hz

Max MVA:500 MVA (three-phase) / 1000 MVA (single-phase)

Max: kV:75 Max. kA & Duration: 200 kA, 1 s

Synthetic Installation:Highest rated parameters of the tested circuit-breaker, 170 kV, 50 kA, highest TRV peak is 330 kV

Short-circuit Testing Facilities

Low Voltage Tests:Short-circuit strenght test on low-voltage switchgear and control gear assemblies, busbar trunking systems till 200 kA-1s

Medium Voltage Tests:Short-circuit tests on distribution transformers. Making and breaking tests of alternating-current circuit-breakers, switches and switch disconnectors. Breaking tests of current limiting fuses. Internal arc tests on metal-enclosed switchgears and prefabricated substations. Power arc tests on insulators and insulator sets.

High Voltage Tests:Making and breaking tests of alternating-current circuit-breakers in single-phase synthetic test circuit with DC recovery voltage. Short-circuit tests on reactors and power transformers.

Heat Run / Short-circuit Temperature Rise Tests:Neutral Grounding Resistors, conductors and fittings.

Tests on Insulator Strings:Short-circuit and power arc tests on insulator strings.

Other Types of High Power Tests Offered:Short-time and peak withstand current tests of LV, MV and HV equipment. Short-circuit tests on cables and cable accessories. Short-circuit tests on overhead line conductors or bundled conductors with max. length of 250 m. Short-circuit tests on surge arresters.

High Current Laboratory

Temperature Rise Tests: Circuit-breakers switches, disconnectors, transformers, current and voltage transformers, enclosed switchgears, fuses, cables, conductors, busbars, prefabricated substations.

Constant Test Current Temperature Rise Test: 10 kA

Long-term Electrical Aging Test on Fitting: 8 kA

Short-circuit power100 MVA

Mechanical Test Capabilities

• Stress-strain test on conductors,

• Breaking load test on conductors, fittings and insulators up to 300 kN.

• Thermo-mechanical test on insulators (-40 … +65 °C)

• Creep test on conductors

• Type test on Aeolian vibration dampers (stockbridge)

• Type tests on spacers/spacer dampers

Other Test Capabilities

Measurement Capabilities:• Multichannel optical transient recorders up to 40 MHz

• Data logging systems up to 160 measuring points

• Digital high-speed camera up to 6000fps

• Binocular, image intensifier (photo multiplier) equipment

• Day-light UV camera for detection of visible corona

• Infrared thermo camera for detecting hot spots and visualize temperature distribution.

Additional Special Facilities:• Faraday cage

• Accuracy tests

• Electrical and mechanical ageing tests

• AC/DC resistance test.

LOCA (Loss of Coolant Accident) Laboratory

The laboratory is specialized for unique tests and qualification of electric apparatus of nuclear power plant according to IEEE. The tests are performed in equipment having different test volumes, their max. parameters are: dry temperature 20-250°C; wet (vapour) temperature 250°C; pressure 0-6 bar.

Product Certification Office

Accredited according to standard: ISO/IEC 17065