Podnikatelska 267

Praha 9 - Bechovice, 190 11

Czech Republic

Overview

Fully independent and internationally recognized High Voltage Testing Laboratory with more than 65 years of continuous experience in the testing and research.

The High Voltage Testing Laboratory has been accredited acc. to ISO / IEC 17025 for more than 25 years.

EGU – HV Laboratory provides customers with fully secure live video streaming from the testing, if required.

Key Contact Personnel:

Jan Lachman, Managing Director lachman@eguhv.com

Marek Brosch, Testing Lab Manager brosch@eguhv.com

Major Markets Served: Europe, USA, Asia, Middle East, Africa, Australia

Other Website: www.hvindependent.com

EGU – HV Laboratory is officially approved for the testing from the following companies: DEWA, TRANSCO, SEC, TNB Malaysia, NTDC Pakistan

[the_ad id=”13925″]

Services

High Voltage Laboratory

Number of Employees in High Voltage Laboratory: 15

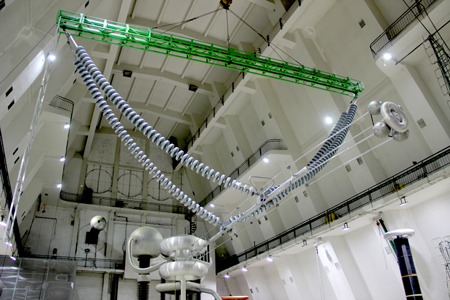

Main Testing Hall (ZH1): 54 m length x 25 m width x 24 m height

Secondary Testing Hall (ZH2): 30 m length x 12 m width x 11 m height

Third Testing Hall (ZH3): 35 m length x 18 m width x 10 m height

Dielectric Testing Facilities:

|

Max. Voltage / Current |

Standard/Remarks |

|

| Impulse Testing: | ||

| Lightning Impulse |

2600 kV |

IEC / IEEE |

| Switching Impulse |

1600 kV |

IEC / IEEE |

| Impulse Generator 1.8 MV |

1.8 MV / 180 kJ |

power cables testing |

| A.C. Testing: | ||

| Cascade Transformer |

1200 kV / 1 A |

IEC / IEEE |

| Modular Type Series Resonant System MSR 600/1200 |

600 kV / 1200 kVA |

power cables testing |

| D.C. Testing: |

up to 300 kV |

IEC / IEEE |

| Partial Discharge & RIV Testing: |

800 kV |

IEC / IEEE |

| Capacitance & Tan ∂ Testing: |

800 kV |

IEC / IEEE |

| Pollution Testing |

salt fog / solid layer / special tests |

IEC 60507 |

| Temperature Rise Testing of Bushings |

6 000 Amp |

IEC 60137 / IEEE Std C57.19.00 |

| Heat cycle tests on fittings |

3 000 Amp |

IEC 61284 / IEC 61238-1 / |

| Electrical type tests on power cables |

up to Um = 420 kV |

IEC 60840 / IEC 62067 |

| Modular Type Series Resonant System MSR 600/1200 |

600 kV / 1200 kVA |

power cables testing |

• Five test chambers for the tracking and erosion salt fog testing as per IEC 62217.

• One test chamber (475 m3) for the pollution testing as per IEC 60507.

• Tracking wheel test as per IEC / ANSI

Other Test Capabilities

RIV & Corona Measurement: 800 kV -IEC 60437, CISPR 18-2, IEC 61284

Temperature Rise Tests: Bushings up to 550 kV / all types / IEC + IEEE

Pollution tests: Salt fog testing, solid-layer testing (clean fog, flow-on method, rapid clean fog etc.)

Mechanical Tests: Horizontal testing machine – tension / max. load 600 kN / max. length 5 m

Vertical testing machine – cantilever / max. load 30 kN

Thermal Mechanical Tests: Three thermal – mechanical chambers with max temperature range – 60 ºC to + 80 ºC; up to 500 kN and 3,2 m in length (tensile) & up to 50 kN (bending)

Insulator Sets: Dielectric type testing of insulator sets – RIV / AC / LI / SI – Dry / Wet

Setups according to IEC 60383-2 and customer requirements.

High Voltage Bushings: Type testing of insulator bushings acc. to IEC and IEEE standards.

Electrical testing, cantilever testing, tightness testing, temperature rise testing, thermal stability testing

Insulators: Full design and type testing of glass, porcelain and composite insulators as per IEC, ANSI and other standards. Hollow Core Insulators: Design and Type testing – interface test, internal pressure test, leakage test.

Environmental and On Site Tests: Measurement of pollution degree and state of external insulation, measurements of radio interferences, electric and magnetic fields, audible noise and overvoltages, simulation in ATP/EMTP.

Other tests: Performed on hollow core insulators: design and type testing – interface test, internal pressure test, leakage test, surge arresters, bushings, disconnectors, switchgears

R&D Activities: Overhead line design, insulation coordination studies, ferroresonances, HV cable performance studies, Transient-overvoltage studies and measurements, international research activities, standardization.

Activities in IEC and CIGRE: Company experts are active in IEC TC 36, CIGRE SC D1, C4 and B2.